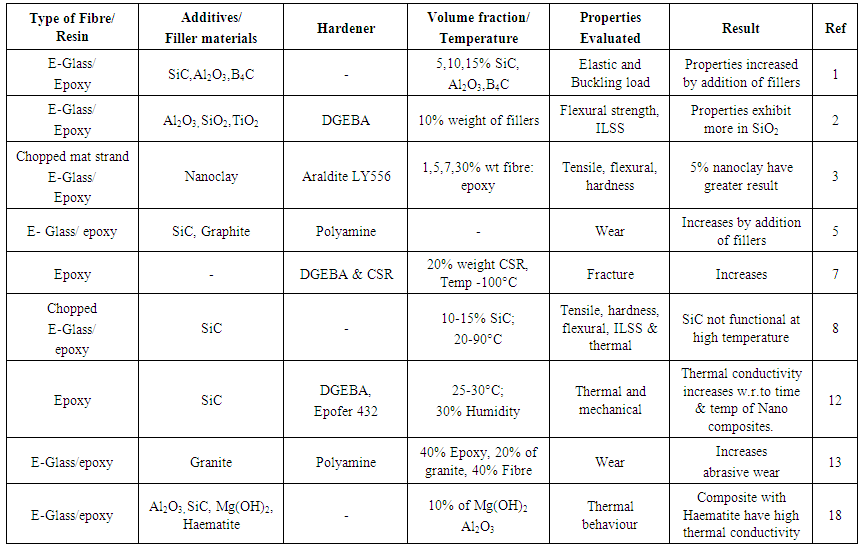

Glass epoxy composite material with outstanding electrical properties g10 fr 4 is a composite material that consists of glass fabric electrical grade epoxy resin.

Glass epoxy sheet properties.

G10 fr 4 glass epoxy composite laminate material.

G9 g10 fr4 glass epoxy sheet g10 and fr4 glass cloth reinforced epoxy natural is typically a yellowish to light green color.

Epoxy sheet with g10 g11 and fr4.

Epoxy resins are widely used in electronic applications because they are virtually impervious to moisture.

This product first introduced in the 1950 s has characteristics of high strength low moisture absorption excellent electrical properties and chemical resistance.

Fr 4 or fr4 is a nema grade designation for glass reinforced epoxy laminate material.

1982 epoxy glass cloth laminated sheet is made of alkali free e glass cloth impregnated with epoxy resins by processing under heat and pressure.

Epoxy glass fibre sheets are available in all types.

Fr stands for flame retardant and does not denote that the material complies with the standard ul94v 0 unless testing is performed to ul 94 vertical flame testing in.

What is g10 material.

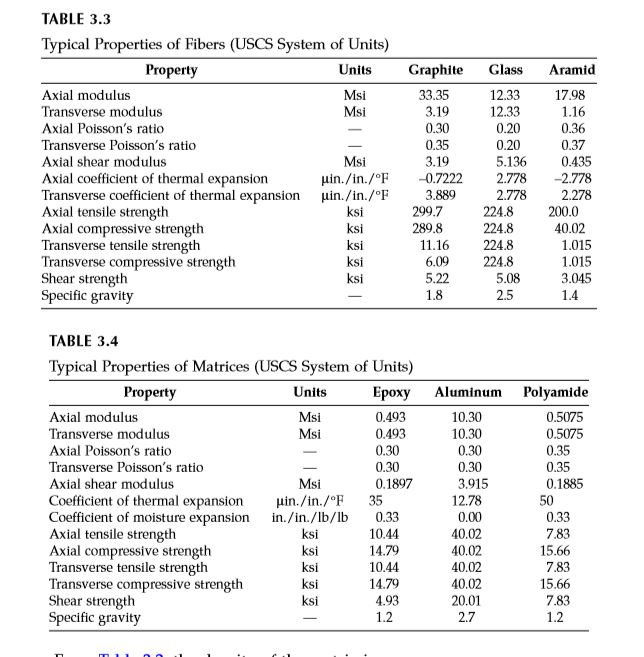

Glass epoxy g 10 fr4 g 11 characteristics.

As a thermoset material glass epoxy has outstanding mechanical and electric strength as well as good dielectric properties.

Fr 4 and g 10 are the most versatile all around of the laminate grades and are made by impregnating an epoxy resin binder into continuous glass woven fabric.

The material is extremely strong and stiff has a low coefficient of thermal expansion and outstanding electrical properties.

Epoxy glass fibre sheets are used for its high insulating properties in electrical as well as thermal also and good mechanical properties.

Fr 4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant self extinguishing.

We are sadhana fibre glass industries manufacture of epoxy sheet as per per is.